Enginartists

Need some motivation? Or just want to feel bad about yourself? Check out what these Enginartists are up to!

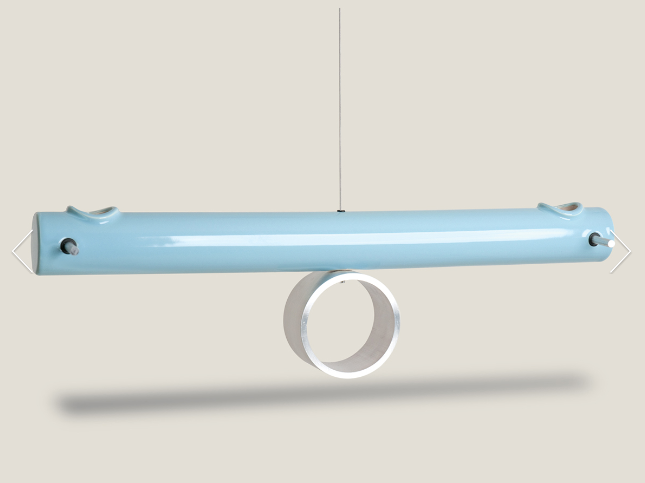

Sculptural Furniture By Sebastian ErraZuriz

Kinetic Art and the Engineer Within

Career

Career Advice and Musings.

Top Ten Financial Planning Steps For Engineers

Financial Planning is more crucial to our personal wealth then ever before. I mean, it was always important, but past

My Art

It's not easy be vulnerable and letting others see your creative work, so you might as well put it on the web for the world to see. What could go wrong?

What is Art?

I have the answer! I know there are thousands of people, academic and otherwise, debating this same question but I

Home Improvement

I do some strange and/or ambition things to my home. Let me show you what I have been up to.

Unique DIY Mudroom Floating Bench With Storage Cabinets

Let me show you one way to make a floating mudroom bench with a waterfall edge!